According to relevant data show that for nearly 10 years, the world's cement powerhouses Germany, Switzerland and other countries of the cement industry rising strength of cement, clinker useage amount general trend of decline. Future development trend of cement in Germany is still the traditional Portland cement is mixed with slag, fly ash, shale, pozzolan, limestone sintering type II of low clinker cement varieties of replaced.

slag

slag powder

after partly replace clinker

after partly replace cement

Slag powder is a superior performance of concrete admixture, mixed with slag powder in cement production can improve the cement strength of 28 d 15% - 20%, 42.5 level of cement configuration; Mixed with slag powder in concrete production can replace 10 ~ 50% of cement.Read more>>

Currently, tangshan jidong cement, and a number of large cement plant in henan meng electricity cement used in slag powder as cement mixed material, and greatly reduce production costs, improve the comprehensive performance and concrete in the late strength of cement has obtained the good effect.

| system scheme | ball mill | vertical roller mill |

| system power consumption(kWh/t) | 80 | 38 |

| Ratio of water to dry(%) | 10(Separate drying) | 20(drying in mill) |

| Adaptability of granularity | bad | good |

| The main reasons influencing operation rate | To run a certain cycle ball to remove iron slag | Roller and plate lining repair after abrasion |

| large-scale | difficutly | easy |

Significant energy saving effect of vertical mill machine will replace grinding ball mill energy consumption is too large

An annual output of 600000 tons of vertical mill system in ball mill system energy saving: 42kWh/t X 600000 T= 25,2millionkWh

Vertical mill grinding system covers an area of about 70% of the ball mill system, lower construction costs

Compared with ball mill system, vertical grinding machine has an obvious advantage in mineral powder metal recycling, vertical mill tons of ore powder metal recovery was 0.2 0.3%, ball mill is 0; With an annual output of 600000 tons of ore powder line, recycled scrap is about 1200-1800 tons/year

Ore than ball mill in the production of uniform particle size distribution, good liquidity

Vertical mill system revealed the specific surface area of 430 m squared/kg, kuangfen activity can achieve maximum play to 28 days

Learn from henan meng electricity experiment data, incorporating mineral powder can improve the cement strength of 28 d 15% 20%

Vertical mill grinding system in lower production costs, energy conservation and consumption reduction, kuangfen quality, etc., are better than that of the ball mill system.

Vertical mill grinding system produces the type of product will win ball mill in terms of quality and price system in the production of mineral powder, its kuangfen huge competitive advantage would be preferred in cement plant, mixing station and other purchasers of best-selling products.

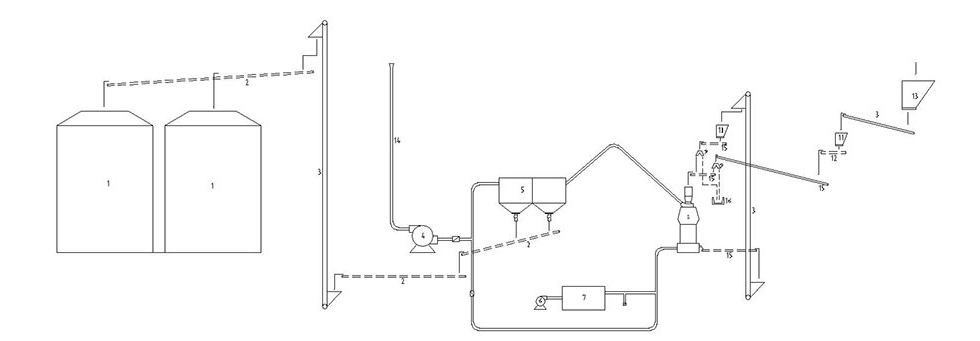

Wet slag storage and transportation: wet slag by motor transport into the factory, the discharge hopper, belt conveyor into the slag heap tent storage and discharge material by forklift, hopper, through constant feeder measurement by belt conveyor after delivery directly to the slag vertical grinding machine, electromagnetic iron remover on belt conveyor is set in addition to iron.

Slag powder grinding and storage: wet slag by quantitative feeding said measuring directly into the roller mill by belt conveyor after feeding mouth, after drying and grinding of slag powder after long bag pulse dust collector to collect by air transport chute, winding machine into the slag powder library.

| Model and specification | diameter of millstone D(mm) | median diameter of roller D(mm) | quantity of roller n | standard installed power P(kW) | Standard ability(t/h) |

| GRMS26.21 | 2600 | 1600 | 2 | 1000 | 30 |

| GRMS33.31 | 3300 | 1700 | 3 | 1600 | 45 |

| GRMS35.41 | 3500 | 1800 | 4 | 1800 | 60 |

| GRMS40.41 | 4000 | 1900 | 4 | 2240 | 70 |

| GRMS43.41 | 4300 | 2120 | 4 | 2800 | 90 |

| GRMS46.41 | 4600 | 2240 | 4 | 3150 | 90 |

| GRMS48.41 | 4800 | 2240 | 4 | 3550 | 125 |

| GRMS50.41 | 5000 | 2360 | 4 | 3800 | 140 |

| GRMS53.41 | 5300 | 2500 | 4 | 4200 | 150 |

| GRMS56.61 | 5600 | 2500 | 6 | 5000 | 160 |

| The Great Wall of xinxiang machinery annual output of 600000 tons of ore powder production line running parameters | |

| Designed production capacity(t/h) | 90 |

| Actual propduction capacity(t/h) | 105 |

| model | GRMS46.41 |

| Finsh fineness(m²/Kg) | 430 |

| Sigle mill power consumption(kWh/t) | 28.5 |

| System power consumption(kWh/t) | 37 |

| Metal recovery rate of one tone slag(%) | 0.2~0.3 |

The mineral powder production line adopts the totally enclosed design, green environmental protection, by the end of 2013, the whole system runs stably, without any fault.

| Project | index | actual motion |

| commissioning date | commissioning date | april,2011 |

| investment calculations | total investment | 50million |

| cost account | cost of raw material | 70 yuan/t |

| Production costs (including wages, electricity, coal, maintenance fees, cost of sales, etc.) | 50 yuan | |

| profit calculation | Price | 160 yuan/t |

| profit per ton | 30 yuan/t | |

| annual profit | 30×60million=1800million | |

| economic benefit | 2 years and 10 months recycling all investment (now in a state of pure profit) | |

| The quality of slag powder | Specific surface area | 430 m²/kg |

| 7 d activity index | Can reach 100% | |

| activity index | Achieve GGBS national standard S95 level above | |

| Product Sales | Product sales region | Product sales in xinxiang, shangqiu, xuchang, etc |

| inspection unit | Henan built courtyard building materials inspection co., LTD |

| Inspection unit address | Zhengzhou hongqi road no. 34 (henan building materials research and design institute) |

| The sample name | used in the cement and concrete in graining of blast furnace slag powder |

| entrusting party | xinxiang great wall slag powder co.,ltd |

| Entrust unit address | Gaoville Mengzhuang Town, Huixian City |

| production unit | xinxiang great wall slag powder co.,ltd |

| sample size | 5KG |

| The sample status | gray mealy |

| Sample grade S95 | S95 |

| Sample submission date | Deliver date on June 15, 2011 |

| Test Date | Inspection date on June 15, 2011 |

| inspection item | Density, specific surface area, activity index, fluidity ratio, water content, sulfur, chlorine ion trichloride, ignition loss |

| Test according to | GB/T18046--2008 |

| Conclusion | The qualified all items |

Supplier of roller for Denmark FLSmidth

With independent steel casting factory, shorting the delivery date.

Partner of Shanghai Bao Steel for the steel slag production line.

With Chinese famous auxiliary engine, quality guaranteed.

With the sample slag powder production line, provide the online training.

Provide EPC turnkey service

Free test slag materials, provide project drawings.

Provide slag powder ratio, ensure the high quality

Design and manufacture products according to customers’ require

Design the place in site, design best process and scheme.

Repair and welding accessories for many years to provide services

Free on-site service within a year

365 days no holiday Customer Service Online

24 hours phone service

Add: National Sustainable Development Experiment Area, Mengzhuang Town, Huixian City, Henan Province.

Email:[email protected]

Tel:+86-371-55019608